Pharmaceutical Primary Packaging: Know The Impact On Medicine Industry

- - Category: Alternative Medicine

- - 21 Dec, 2023

- - Views: 44

- Save

The global pre-sterilized / ready to use pharmaceutical packaging market is estimated to be worth USD 9.18 billion in 20

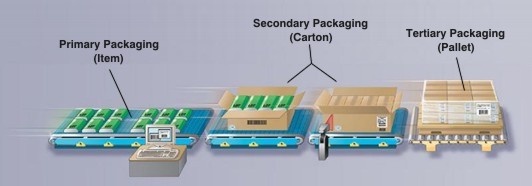

Pharmaceutical primary packaging refers to the immediate container or packaging in direct contact with medications. It serves as a critical barrier to protect drugs from external influences, ensuring their stability, safety, and efficacy from production through to patient use. Primary packaging materials, such as bottles, vials, ampoules, blister packs, and syringes, are specifically designed to maintain the integrity of pharmaceutical products, shielding them from moisture, light, air, and contaminants. The selection of appropriate primary packaging materials and configurations is pivotal in preserving drug quality, preventing contamination, and adhering to regulatory standards while considering factors like compatibility, stability, and ease of administration for patients.

The global pre-sterilized / ready to use Pharmaceutical Packaging Market is estimated to be worth USD 9.18 billion in 2023 and is expected to grow at compounded annual growth rate (CAGR) of 8.74%, during the forecast period.

The impact of pharmaceutical primary packaging in the medicine sector is profound and multifaceted. It directly influences various aspects of medication quality, safety, and usability throughout the drug lifecycle:

- Preservation and Stability: Primary packaging acts as a shield, safeguarding medications from environmental factors like moisture, light, air, and contamination. This protection is crucial for preserving the drug's chemical stability, potency, and efficacy from manufacturing to patient use.

- Safety and Contamination Prevention: It plays a pivotal role in preventing contamination or tampering, ensuring that medications remain sterile and safe for consumption. Properly sealed and designed packaging reduces the risk of microbial contamination or exposure to harmful elements.

- Compliance and Regulatory Standards: Pharmaceutical primary packaging must comply with stringent regulatory standards to ensure that medications meet safety, efficacy, and quality requirements. Packaging materials and configurations must adhere to specific guidelines set by regulatory bodies to guarantee patient safety.

- Patient Compliance and User Experience: Packaging design influences patient adherence to medication regimens. User-friendly packaging, such as easy-to-open blister packs or appropriately labeled containers, enhances patient understanding and compliance with dosage instructions.

- Product Differentiation and Branding: Packaging design also plays a role in product differentiation and branding. Unique and recognizable packaging can contribute to brand identity, aiding in market positioning and patient recognition of specific medications.

- Waste Management and Sustainability: The choice of packaging materials impacts the environmental footprint of the pharmaceutical industry. Efforts toward using recyclable, eco-friendly materials and optimizing packaging design for reduced waste align with sustainability goals.

Overall, pharmaceutical primary packaging profoundly impacts medication quality, safety, regulatory compliance, patient adherence, and environmental sustainability within the medicine sector, making it a critical component of the pharmaceutical lifecycle.

In 2023, the growth trajectory of pharmaceutical primary packaging continues to be dynamic and innovative, driven by a combination of factors shaping the healthcare landscape. Advanced materials and technologies are reshaping packaging solutions, focusing on enhanced drug stability, patient safety, and environmental sustainability. The industry sees a surge in demand for smart packaging solutions, integrating features like temperature monitoring, tamper-evident seals, and interactive labeling to ensure medication integrity and patient engagement. Moreover, with a spotlight on personalized medicine and biologics, primary packaging evolves to accommodate specialized storage and delivery requirements for these sensitive therapies. Efforts towards eco-friendly packaging options and adherence to stringent regulatory standards further steer the growth, fostering a landscape of primary packaging that's not just protective but also responsive to evolving healthcare needs and global sustainability goals.

Segmentation:

By Material:

- Plastics

- Paper & paperboard

- Glass

- Metal

- Others

By Drug Delivery

- Oral Drugs

- Injectables

- Topical

- Ocular/ Ophthalmic

- Nasal

- Pulmonary

- Transdermal

- IV Drugs

- Others

By Type

- Plastic bottles

- Blister

- Labels & accessories

- Caps & closures

- Pre-filled syringes

- Medical specialty bags

- Temp controlled packaging

- Pouches & strip packs

- Pre-filled inhalers

- Vials

- Ampoules

- Medication tubes

- Jars & Canisters

- Cartridges

- Others

The future of pharmaceutical primary packaging holds numerous exciting prospects driven by technological advancements, sustainability goals, and evolving healthcare needs:

Smart Packaging Innovations: Integration of smart technologies like RFID tags, sensors, and near-field communication (NFC) enables real-time monitoring of medication usage, expiration dates, and temperature-sensitive drugs. This fosters improved patient adherence and safety.

Personalized Medicine Adaptation: As the focus on personalized medicine grows, primary packaging will evolve to accommodate individualized dosing, specialized delivery systems, and tailored packaging configurations for precision therapies.

Environmentally Sustainable Solutions: The industry is moving towards eco-friendly packaging options, utilizing biodegradable materials and reducing plastic waste. Innovations in recyclable, compostable, and reusable packaging align with sustainability goals.

Advanced Drug Delivery Systems: Primary packaging will incorporate sophisticated drug delivery mechanisms, such as micro/nanostructures or controlled-release formulations, improving efficacy and patient convenience.

Regulatory Compliance and Safety Enhancement: Continued emphasis on compliance with stringent regulatory standards will lead to innovations in tamper-evident seals, child-resistant closures, and anti-counterfeiting measures to enhance drug safety.

3D Printing and Customization: Advancements in 3D printing technology will enable on-demand, personalized packaging designs, catering to specific patient needs and dosage requirements.

Biopharmaceutical Packaging Evolution: The rise of biologics and complex molecules will prompt the development of specialized packaging solutions, ensuring the stability and integrity of these sensitive therapies.