Understanding The Basics: A Comprehensive Guide To Hand Lever Valves

- - Category: Industrial

- - 04 Mar, 2024

- - Views: 35

- Save

With a deeper understanding of hand lever valve components, you can make informed choices.

Hand lever valves are manually operated valves that use a lever to control the flow of fluids (liquids or gases) in pipes or tubes.

- Versatile Application: They are widely used in various industries due to their ease of use, affordability, and durability. They are ideal for applications requiring frequent on/off switching or flow rate adjustments.

- Common Functions: These valves come in two-way (open/close) and three-way (divert flow) configurations, allowing for control over flow direction and pressure.

For reliable hand lever valves and a vast selection, look no further than top hand lever valve manufacturers in India. Their expertise ensures you get the perfect valve for your specific needs.

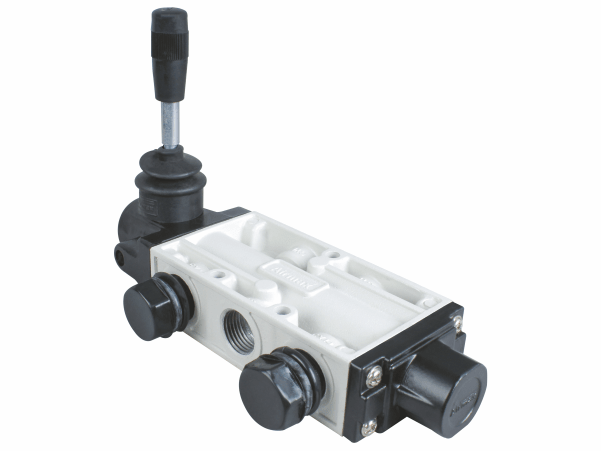

Anatomy of a Hand Lever Valve: Components and Structure

Hand lever valves, crucial for controlling fluid flow, offer simple operation with a hand-operated lever. Here's a breakdown of their anatomy:

- Lever: The hand lever, the namesake of the valve, translates manual force into opening or closing the valve.

- Valve Body: This houses the internal components and provides connection points for pipes.

- Stem: Connected to the lever, the stem transmits movement within the valve body.

- Packing: This creates a tight seal around the stem, preventing leaks.

- Seat & Disc: The seat forms a base for the disc, which regulates flow by opening and closing the passage.

With a deeper understanding of hand lever valve components, you can make informed choices. Research reputable manufacturers who prioritize quality and performance.

Operating Principles of Hand Lever Valves: How Do They Work?

Hand lever valves are a common type of valve used to regulate the flow of liquids or gases in various applications. Their simple design and manual operation make them a reliable choice for industrial settings. Here's a quick look at how they work:

- Manual Actuation: A lever is the key component, moved by hand to control the flow.

- Internal Mechanism: The lever connects to an internal element, like a spool or poppet, through linkages or cams.

- Flow Control: Movement of the lever opens or closes specific flow paths within the valve body, regulating the fluid.

- Precise Control: The design of the lever and its movement directly influence the flow rate, allowing for fine-tuning.

For reliable hand lever valves, consider partnering with a Top Hand Lever Valve Manufacturer in India. They can provide valves built for your specific needs and ensure smooth operation within your system.

Types of Hand Lever Valves: Manual, Mechanical, and Hydraulic

Hand lever valves are workhorses in industrial settings, providing precise fluid flow control through a simple lever movement. But did you know there are different types depending on the actuation method? Here's a quick rundown:

- Manual: The most basic type, operated directly by hand for quick on/off control.

- Mechanical: Levers, cams, or linkages connect the hand lever to the valve mechanism, ideal for situations where electrical power is unavailable.

- Hydraulic: The operator lever controls a pilot valve, which in turn directs pressurized fluid to operate the main valve. This offers greater force and control over larger flows.

For top-quality hand lever valves and reliable performance, look no further than leading manufacturers in India. Their expertise ensures you get the perfect valve for your specific needs.

Advantages and Limitations of Hand Lever Valve Systems

Hand lever valves offer a straightforward way to regulate fluid flow with a manual lever. Here's a quick look at their pros and cons:

Advantages:

- Simple operation: The lever provides easy on/off control, ideal for quick adjustments.

- Cost-effective: Their design is relatively inexpensive compared to more complex valves.

- Durable: They can withstand harsh environments due to their robust construction.

Limitations:

- Limited flow control: Lever position typically offers only full-open or full-closed options.

- Not ideal for high-pressure: They may not be suitable for very high-pressure applications.

- Size constraints: Large-scale lever operation can become cumbersome.

For reliable hand lever valve solutions, consider partnering with a Top Hand Lever Valve Manufacturer in India. Their expertise can ensure you get the right valve for your specific needs.

Common Applications of Hand Lever Valves Across Industries

Hand lever valves, with their simple design and manual operation, are workhorses across countless industries. Here's a glimpse of their versatility:

- Manufacturing: Precise control of air cylinders for powering presses, robots, and various equipment.

- Fluid Handling: Regulating air pressure in pumps and valves for efficient transfer of liquids and gases.

- Construction: Easy on/off control of water flow in irrigation systems or temporary lines.

- Agriculture: Precise actuation of pneumatic tools for planting, harvesting, and other tasks.

- Food & Beverage: Controlling flow in filling lines, mixing processes, and sanitation procedures.

Looking for top-quality hand lever valves to optimize your operations? Consider partnering with a leading manufacturer in India. Their expertise ensures reliable and durable valves for all your flow control needs.

Selection Criteria: Factors to Consider When Choosing Hand Lever Valves

Hand lever valves offer simple and reliable flow control, but selecting the right one requires considering several factors:

- Application: What fluid are you controlling? High pressure gases will require different materials than low pressure liquids.

- Flow Rate: How much fluid needs to pass through the valve? Choose a valve size that can handle your flow requirements.

- Material: The valve material needs to be compatible with the fluid and environment. Consider factors like corrosion resistance and temperature tolerance.

- Pressure Rating: What is the maximum pressure the valve will experience? Choose a valve with a pressure rating exceeding your expected operating pressure.

- Durability: For frequent use or harsh environments, consider a lever design built for long-lasting performance.

By carefully considering these factors, you'll ensure optimal performance and longevity from your hand lever valve. To ensure you're getting the best quality, look for valves from a Top hand lever valve Manufacturer in India. These manufacturers will offer a wide selection of valves designed to meet your specific needs.

Installation Procedures for Hand Lever Valves: Best Practices and Tips

Hand lever valves are essential for controlling fluid flow in various applications. Here's a quick guide to ensure a smooth installation:

- Preparation is Key: Before starting, gather the necessary tools as specified by the manufacturer (from a Top hand lever valve Manufacturer in India) and ensure the pipework is clean and free of debris.

- Positioning: Install the valve according to the flow direction indicated on the body. Use pipe threads or flanges for secure attachment, applying thread sealant for threaded connections.

- Tighten Up: Hand-tighten the nuts and bolts evenly following the manufacturer's recommended torque specifications. Avoid over-tightening, which can damage the valve.

- Leak Check: Once installed, close the valve and slowly open an upstream pressure source. Use a suitable leak detection method (soap and water solution is common) to check for leaks at the connections.

- Operational Test: Finally, operate the lever through its full range of motion to ensure smooth operation and proper shutoff.

Following these best practices will ensure a secure and functional hand lever valve installation. Remember, for optimal performance, always refer to the specific installation instructions provided by your chosen Top hand lever valve Manufacturer in India.

Maintenance and Troubleshooting Guide for Hand Lever Valve Systems

Hand lever valves are essential for controlling fluid flow in various applications. As a Top hand lever valve Manufacturer in India, we want to ensure your valves operate smoothly for years to come. Here's a quick guide to keep your hand lever valve system running optimally:

- Regular Inspection: Visually check for leaks, cracks, or damage on the valve body and lever. Ensure all connections are secure.

- Keep it Clean: Contamination can hinder performance. Regularly clean the valve and surrounding area to prevent debris buildup.

- Lubrication Matters: Use the recommended lubricant to maintain smooth operation and extend valve life.

- Troubleshooting Leaks: A minor leak might require tightening the packing nut. For persistent leaks, consult a qualified professional.

By following these simple steps, you can ensure your hand lever valve system functions flawlessly. For superior hand lever valves and expert advice, contact us today!

Future Trends and Innovations in Hand Lever Valve Technology

The humble hand lever valve, a mainstay in industrial settings, is poised for an exciting future. Here's a glimpse of what's ahead:

- Smarter Valves: Look for integration of sensors and digital controls. These "smart valves" will enable real-time monitoring, automated adjustments, and improved efficiency.

- Sustainable Materials: Eco-friendly materials like bioplastics are making inroads, reducing environmental impact.

- Enhanced Durability: Advancements in material science will lead to valves with extended lifespans and improved resistance to wear and tear.

- Focus on User Experience: Ergonomic design will prioritize operator comfort and safety, minimizing fatigue and risk of injury.

Top Hand Lever Valve Manufacturers in India will be at the forefront of these innovations, developing reliable and efficient valves that meet the demands of tomorrow's industries.