Practical Tips To Order Rigid Flex Pcbs In Bulk

- - Category: Industrial

- - 20 Jul, 2023

- - Views: 32

- Save

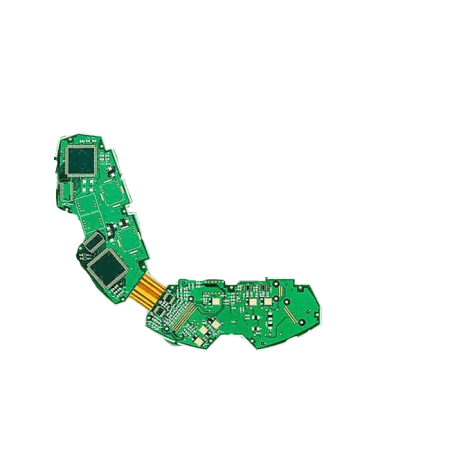

Rigid-flex PCBs are a versatile solution for electronic devices that require both rigid and flexible areas.

Rigid-flex PCBs are a versatile solution for electronic devices that require both rigid and flexible areas. They provide the benefits of reduced assembly steps, improved reliability, and space savings. Before ordering rigid-flex PCBs in bulk, it's crucial to understand their design, manufacturing, and application requirements.

Define Your Specifications

Begin by defining your specific requirements for the rigid-flex PCBs. Consider factors such as dimensions, layer count, material selection, copper weight, impedance control, and any specific testing or certification needs. Clear specifications will help you communicate your needs effectively to the manufacturer.

Choose a Reliable Manufacturer

Selecting a reputable manufacturer is vital when ordering Rigid Flex Printed Circuit Boards in bulk. Look for a manufacturer with a proven track record in producing high-quality rigid-flex PCBs and check their certifications and customer reviews. Additionally, consider their manufacturing capabilities, such as the use of advanced equipment and adherence to quality control standards.

Engage Early in the Design Process

To ensure the success of your rigid-flex PCB order, involve the manufacturer early in the design process. Their expertise can help optimise the design for manufacture ability, reducing potential issues and minimizing costs. Collaboration from the early stages allows for seamless communication and a better understanding of your project requirements.

Design for Manufacturing (DFM) Review

Request a design for manufacturing (DFM) review from the manufacturer before placing the bulk order. This thorough review will help identify any design issues that could impact production and yield. The manufacturer's feedback can lead to design modifications that optimize manufacture ability, improving the overall quality and reliability of the rigid-flex PCBs.

Prototype and Testing

Before committing to a bulk order, consider requesting prototypes of your rigid-flex PCBs for thorough testing and validation. Prototyping allows you to verify functionality, assess performance, and make any necessary design refinements. This step ensures that the final product meets your expectations and minimizes the risk of issues in large-scale production.

Secure Supply Chain and Materials

When ordering rigid-flex PCBs in bulk, it's crucial to ensure a secure supply chain for materials. Work closely with the manufacturer to verify the source and quality of the components, substrates, adhesives, and other materials used in the production process. This helps prevent potential delays, counterfeit parts, or quality issues.

Volume Pricing and Lead Time Negotiation

Bulk orders offer an opportunity for negotiating favorable pricing and lead times. Discuss pricing structures and potential discounts with your manufacturers that make flexible pcb products to ensure competitive rates for your rigid-flex PCBs. Additionally, agree on a reasonable lead time that meets your project deadlines without compromising quality.

Packaging and Shipment Considerations

Consider the packaging and shipment requirements for your bulk order. Work with the manufacturer to determine the best packaging method to protect the rigid-flex PCBs during transit. Discuss logistics and shipping options, considering factors like cost, delivery time, and tracking capabilities to ensure a smooth and timely delivery process.

Continuous Communication

Maintain open and continuous communication with the manufacturer during the bulk order process. Regular updates and feedback exchanges will help address any concerns, clarify specifications, and ensure that the production is progressing as planned. Timely communication reduces the risk of errors and facilitates efficient troubleshooting if any issues arise.

Documentation and Record-Keeping

Maintain proper documentation and record-keeping throughout the bulk order process. This includes detailed specifications, communication records, design revisions, test reports, and any other relevant information. It is essential to have a comprehensive documentation. It helps in case of future reference, order replication, or resolving any disputes.

Feedback and Future Collaboration

Provide feedback to the manufacturer based on your experience with the bulk order. This helps them improve their processes and further enhances the partnership for future collaboration. Sharing your insights, both positive and constructive, can contribute to the continuous improvement of the rigid-flex PCB production.